Spirax Sarco TD42L and TD42H are repairable thermodynamic steam traps, suitable for main line drainage and process load drainage respectively, valve body outer surface treated with ENP nickel plating, energy-saving and oxidation-resistant, equipped with anti-airlock disc to vent air, adaptable to various operating conditions.

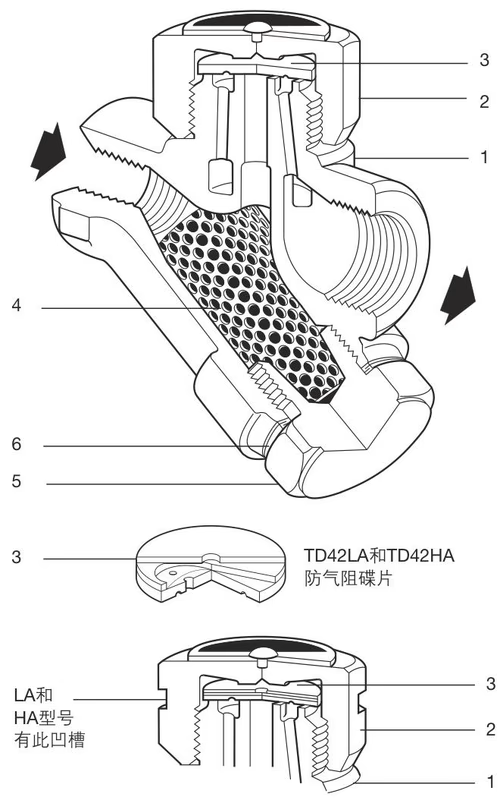

Spirax Sarco TD42L and TD42H series are repairable thermodynamic steam traps designed for different drainage requirements: TD42L has relatively lower rated condensate discharge capacity, primarily for main line drainage applications; TD42H is suitable for process load drainage. When air venting is required in the application, derivative models TD42LA (corresponding to TD42L) and TD42HA (corresponding to TD42H) equipped with anti-airlock discs can be selected.

The outer surface of the valve body in this series is treated with ENP nickel plating, providing both energy-saving and oxidation-resistant advantages, suitable for long-term use under complex operating conditions. The products comply with ISO 6552 standard limitations, certified by UKAS (Cert No. LRQ 0963008) and ISO 9001, ensuring reliable quality.

| Parameter Type | Specific Value |

|---|---|

| Maximum Allowable Temperature (TD42L&TD42H) | 400℃@42 bar g |

| Maximum Allowable Temperature (TD42LA&TD42HA) | 255℃@42 bar g |

| Minimum Allowable Temperature | 0℃ |

| Maximum Operating Pressure (PMO) | 42 bar g |

| Maximum Allowable Pressure (PMA) | 63 bar g@100℃ |

| Maximum Allowable Temperature (TMA) | 400℃@42 bar g |

| Maximum Working Back Pressure | 80% of upstream pressure (valve cannot close if exceeded) |

| Minimum Inlet Pressure for Normal Operation | 0.25 bar, 0.80 bar |

| Design Maximum Cold Water Test Pressure | 95 bar g |

The product provides multiple port size options, covering 3/8", ½", ¾", 1" specifications, adaptable to different pipeline system requirements. Specific dimensions and weights are detailed in the "Dimensions and Weight" section below.

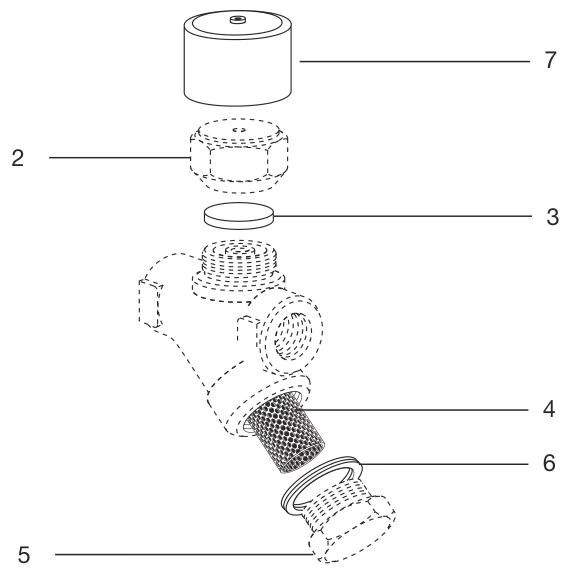

| No. | Component Name | Material Specification | Additional Standard |

|---|---|---|---|

| 1 | Body | Stainless Steel (ENP surface treatment) | ASTM A743 Gr.CA 40 F |

| 2 | Cap | Stainless Steel | AISI 416 |

| 3 | Disc | Stainless Steel | BS 1449 420 S45 |

| 4 | Filter | Stainless Steel | BS 1449 304 S16 |

| 5 | Filter Cover | Stainless Steel | AISI 416 |

| 6 | Filter Cover Gasket | Stainless Steel | BS 1449 304 S16 |

| 7 | Thermal Insulation Cover (Optional) | Aluminum | - |

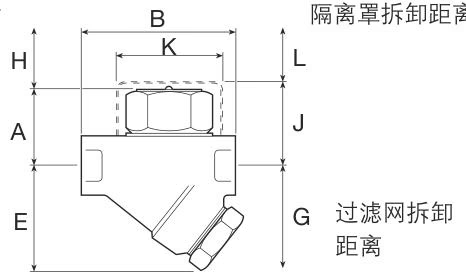

Unit: Dimensions in mm, Weight in kg

| Port Size | A | B | E | G | H | J | K | L | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 3/8"L | 41 | 78 | 55 | 85 | 20 | 52 | 57 | 38 | 0.80 |

| ½"L | 41 | 78 | 55 | 85 | 20 | 52 | 57 | 38 | 0.75 |

| ¾"L | 44 | 85 | 60 | 100 | 20 | 52 | 57 | 38 | 0.95 |

| 1"L | 48 | 95 | 65 | 100 | 20 | 58 | 57 | 38 | 1.50 |

| ½"H | 41 | 78 | 55 | 85 | 41 | 57 | 57 | 38 | 0.80 |

| ¾"H | 47 | 90 | 60 | 100 | 41 | 63 | 57 | 38 | 1.00 |

| 1"H | 53 | 96 | 66 | 100 | 41 | - | - | - | 1.50 |

| Part No. | Applicable Model and Port Size | Specification (mm) | Tightening Torque (Nm) |

|---|---|---|---|

| 2 | TD42L - All Port Sizes | 36 | 135-150 |

| 2 | TD42H - ½", ¾" | 41 | 180-200 |

| 2 | TD42H - 1" | 55 | 250-275 |

| 5 | - | M28 (32) | 170-190 |

The steam trap is recommended to be installed on a horizontal pipe, with a short descending pipe section upstream to ensure optimal operating performance.

For detailed safety information, installation steps, and maintenance procedures, please refer to the Installation and Maintenance Guide (No.: IM-068-024) provided with the product.

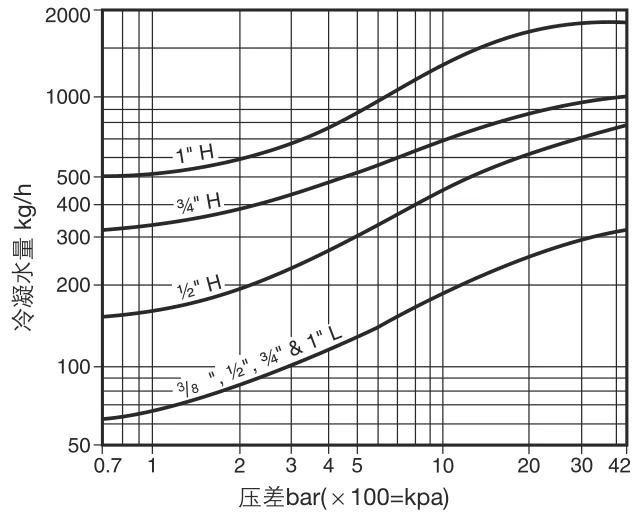

Product discharge is related to condensate quantity and pressure differential, adaptable to drainage requirements under different operating conditions. Specific discharge curves refer to the discharge charts in technical documentation (condensate quantity unit: kg/h, pressure differential unit: bar, ×100=kPa).

This product can provide standard test certificates, which must be clearly specified when ordering.

| Spare Part Name | Applicable Model | Corresponding Part No. |

|---|---|---|

| Disc (3 pieces/set) | TD42L or TD42H | 3 |

| Disc and Filter | TD42LA or TD42HA | 3, 4, 6 |

| Filter and Gasket | TD42L or TD42H | 4, 6 |

| Thermal Insulation Cover | - | 7 |

| Filter Cover Gasket (3 pieces/set) | - | 6 |

When ordering spare parts, specify the steam trap port size and specific model. Example: 1-Filter and Gasket for ½" TD42L thermodynamic steam trap.

This product is recyclable, and when properly disposed of, will not cause negative impacts on the ecological environment.

When ordering, clearly specify the product model, port size, and connection type. Example: 1-Spirax Sarco ½" TD42L thermodynamic steam trap, BSP threaded connection.

Explore similar products in our catalog