MIYAWAKI ES8N/ES8NF Inverted Bucket Steam Trap with extended lifespan SCCV® design, ductile iron body, operating pressure 0.01-1.6MPa, max temperature 350℃, threaded/flanged connections available.

MIYAWAKI ES8N/ES8NF is an inverted bucket steam trap featuring the extended lifespan SCCV® design. By allowing the inverted bucket to float freely within the disc holder, it reduces impact force during condensate discharge and minimizes wear, effectively extending overall equipment service life. Ideal for condensate drainage in steam systems.

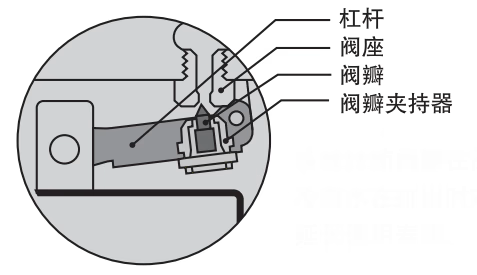

Key components of the SCCV® design:

| Component | Function |

|---|---|

| Lever | Connects bucket to disc, transmits motion |

| Seat | Seals with disc, controls medium flow |

| Disc | Opens/closes with bucket motion, regulates flow |

| Inverted Bucket | Core floating component, senses condensate via buoyancy |

| Disc Holder | Provides bucket floating space, cushions impact |

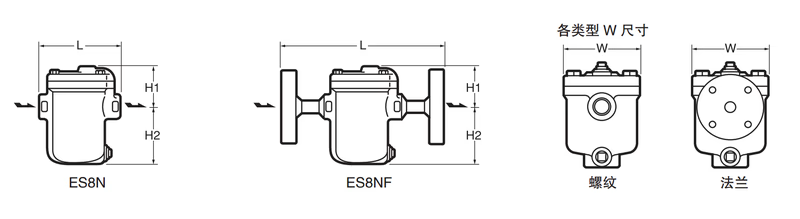

| Model | Connection | DN(mm) | Operating Pressure(MPa) | Max Temp(℃) | Body Material | Dimensions(mm) | Weight(kg) |

|---|---|---|---|---|---|---|---|

| ESSN-5 | Threaded(RC·NPT) | 15 | 0.01-0.5·0.8·1.6 | 350 | Ductile Iron(FCMD40) | L=130, H1=73, H2=90, W=100 | 3.7 |

| ESSN-8 | Threaded(RC·NPT) | 20 | 0.01-0.5·0.8·1.6 | 350 | Ductile Iron(FCMD40) | L=135, H1=73, H2=90, W=100 | 3.9 |

| ESSN-16 | Threaded(RC·NPT) | 25 | 0.01-0.5·0.8·1.6 | 350 | Ductile Iron(FCMD40) | L=175, H1=73, H2=90, W=100 | 5.3 |

| ESSNF-5 | Flanged(F·HF) | 15 | 0.01-0.5·0.8·1.6 | 350 | Ductile Iron(FCMD40) | L=195, H1=73, H2=90, W=100 | 5.7 |

| ESSNF-8 | Flanged(F·HF) | 20 | 0.01-0.5·0.8·1.6 | 350 | Ductile Iron(FCMD40) | L=215, H1=68, H2=95, W=100 | 6.8 |

| ESSNF-16 | Flanged(F·HF) | 25 | 0.01-0.5·0.8·1.6 | 350 | Ductile Iron(FCMD40) | L=215, H1=68, H2=95, W=100 | 6.8 |

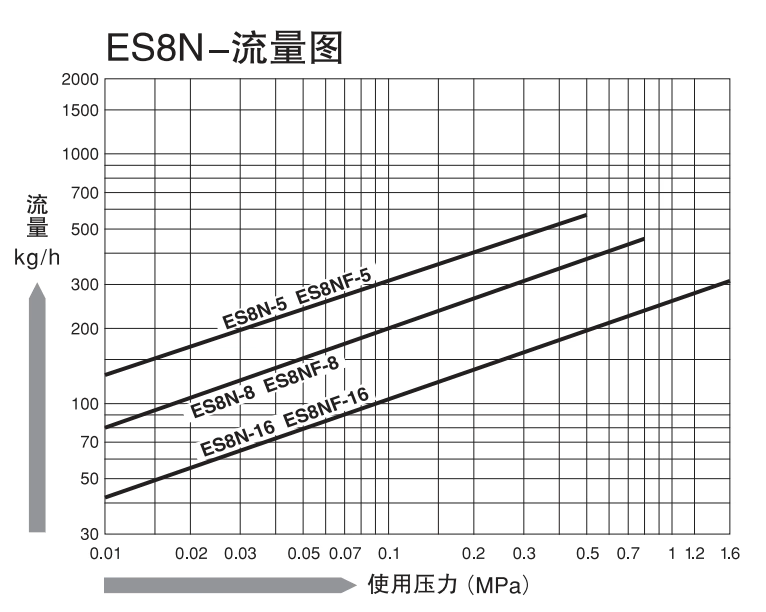

The flow vs operating pressure relationship for ES8N can be referenced in the flow chart. Condensate discharge flow (kg/h) increases linearly with pressure at different operating conditions, suitable for various steam system load requirements.

Explore similar products in our catalog