Spirax Sarco Fig12 ductile iron Y-type strainer uses threaded connection, equipped with stainless steel or alloy filter mesh, compliant with European 97/23/EC Directive, temperature resistant up to 260℃, pressure resistant up to 25 bar g, supports multiple port sizes, optional blowdown/discharge valve installation, suitable for steam, gas and liquid system filtration.

Spirax Sarco Fig12 ductile iron Y-type strainer is a high-efficiency device specifically designed for industrial fluid filtration, using a ductile iron body combined with a carbon steel cap, fitted with high-precision filter mesh to effectively capture impurities in the medium and protect downstream equipment for safe operation. The product complies with the European Pressure Equipment Directive 97/23/EC and is ISO 9001 certified, supports BSP or NPT threaded connections, and allows selection of filter mesh with different apertures and mesh sizes according to actual requirements. The cap can be drilled and tapped to install blowdown or discharge valves as needed, suitable for steam, gas and liquid systems.

| Filter Mesh Material | Optional Aperture | Optional Mesh Size |

|---|---|---|

| Stainless Steel 316L | 0.8mm, 1.6mm, 3mm | 40 mesh, 100 mesh, 200 mesh |

| Monel Alloy | 0.8mm, 3mm | 100 mesh |

| Strainer Port Size | Blowdown Valve Connection | Discharge Valve Connection |

|---|---|---|

| 1/2" | 1/4" | 1/4" |

| 3/4", 1" | 1/2" | 1/2" |

| 1 1/4", 1 1/2" | 3/4" | 3/4" |

| 2" - 3" | 1 1/4" | 3/4" |

| Port Size | 1/2" | 3/4" | 1" | 1 1/4" | 1 1/2" | 2" | 2 1/2" | 3" |

|---|---|---|---|---|---|---|---|---|

| Aperture 0.8mm, 1.6mm, 3mm / 40 mesh, 100 mesh | 3.6 | 11 | 15.5 | 26 | 41 | 68 | 82 | 115 |

| 200 mesh | 3.6 | 9 | 13.0 | 21 | 35 | 55 | 66 | 93 |

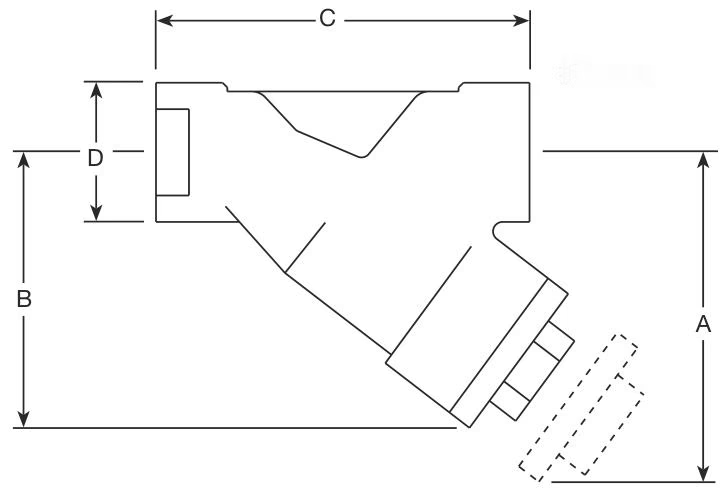

| Port Size | A (mm) | B (mm) | C (mm) | D (mm) | Mesh Area (cm²) | Weight (kg) |

|---|---|---|---|---|---|---|

| 1/2" | 87 | 55 | 79 | 32 | 25 | 0.47 |

| 3/4" | 110 | 65 | 93 | 36 | 42 | 0.77 |

| 1" | 125 | 78 | 110 | 48 | 71 | 1.40 |

| 1 1/4" | 155 | 103 | 140 | 60 | 135 | 2.15 |

| 1 1/2" | 190 | 115 | 153 | 65 | 161 | 3.30 |

| 2" | 230 | 140 | 177 | 76 | 251 | 5.10 |

| 2 1/2" | 274 | 177 | 230 | 94 | 406 | 7.30 |

| 3" | 280 | 183 | 237 | 105 | 406 | 7.50 |

Note: A is the length dimension, B is the safety distance, C is the removal distance, D is the connection-related dimension, and weight is approximate.

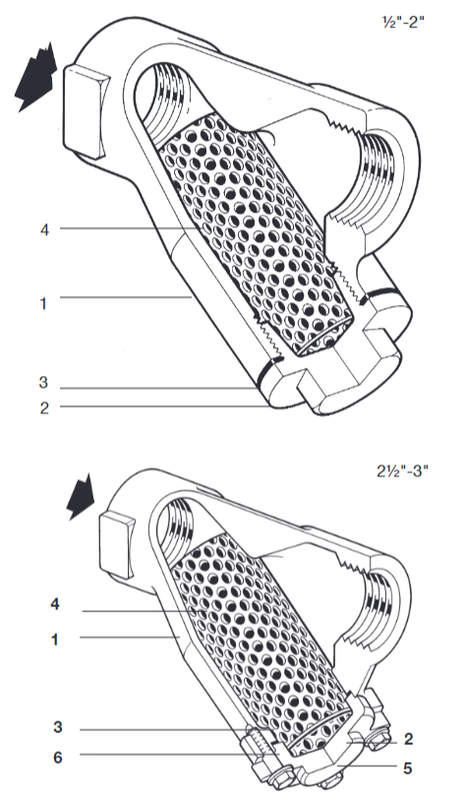

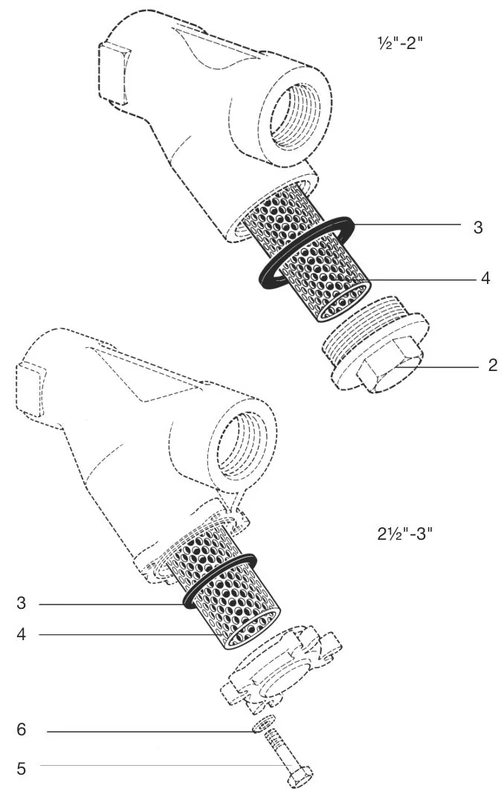

| No. | Component Name | Material Specification |

|---|---|---|

| 1 | Body | Ductile Iron (DIN 1693 GGG 40) |

| 2 | Cap | Carbon Steel (1.0460, ASTM A105N) |

| 3 | Cap Gasket | Reinforced Laminated Graphite (with thin stainless steel support ring) |

| 4 | Filter Mesh | Stainless Steel 316L (standard), Monel Alloy (optional) |

| 5 | Bolt | Carbon Steel (BS 3692 Gr.8.8) |

| 6 | Washer | Carbon Steel (BS 4320 TI Form A) |

The product is recyclable and, when disposed of according to standard procedures, will not cause environmental harm.

| Spare Part Name | Specification Description | Notes |

|---|---|---|

| Filter Mesh | Must specify material (Stainless Steel 316L/Monel Alloy), aperture/mesh size, applicable strainer port size | Core spare part |

| Cap Gasket | Reinforced laminated graphite material with stainless steel support ring | Recommended to order in sets of 3 |

Spirax Sarco 2" Fig12 ductile iron strainer, BSP threaded connection, stainless steel filter mesh aperture 0.8mm

| Port Size | Bolt Specification | Torque Range (N·m) |

|---|---|---|

| 1/2" | M28 | 38 - 40 |

| 3/4" | M32 | 42 - 48 |

| 1" | M42 | 70 - 80 |

| 1 1/4" | M56 | 124 - 144 |

| 1 1/2" | M60 | 164 - 184 |

| 2" | M72 | 234 - 264 |

| 2 1/2", 3" | M12 | 50 - 55 |

Explore similar products in our catalog